Throughout history, wholesalers and distributors have played an important part in the product distribution chain. Distribution firms are seeing a plethora of opportunities and challenges as customer expectations as well as technology have advanced at an exponential pace. Having the proper tools to efficiently plan, manufacture, transport and deliver products that customers want at the correct time is essential for success. Purchasing items from OMEs or their suppliers and distributing them to retailers and end-consumers are all part of the process of distribution.

Monitoring and analyzing each distribution sub-process will be difficult if they are manually controlled using multiple systems. End-to-end operations in a distribution firm can be automated by using an ERP solution, which eliminates the risk of human-related mistakes and minimises the time-consuming manual operations. Enterprise Resource Planning (ERP) systems are business management platforms that distributors can use to gather, store, manage, and transmit data across departments. ERP systems allow data to be exchanged across departments in real-time to simplify procedures and automate routine activities.

What is the difference between manufacturing and distribution industry?

Manufacturing and distribution business operations undoubtedly share certain business processes from a macro-level perspective. Identification of potential consumers, order to cash procedure, and supply chain management are all quite similar. Upon closer inspection, order quantity and order volume are where they diverge. Distributors purchase in bulk from manufacturers and then sell in much smaller amounts to retail outlets or end-user consumers. The marketing and logistics requirements are handled by the distributors rather than the manufacturers. Thus, it can be said that the manufacturing and distribution industries have distinct technology needs as they are two separate verticals that operate in different areas of the supply chain.

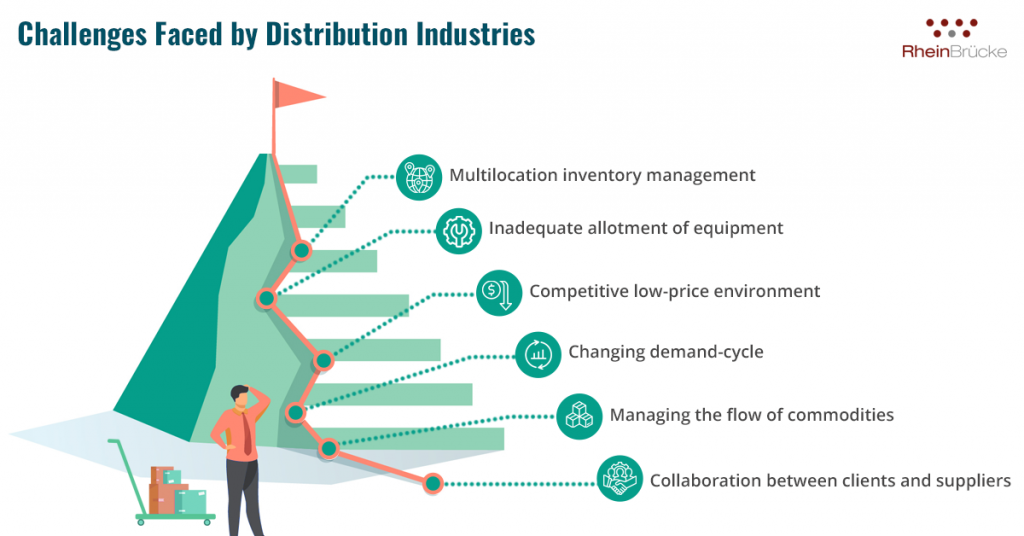

Some of the unique challenges faced by distributors are:

- Collaborating with customers and suppliers

- Managing traceability of merchandise

- Handling multiple divisions dealing with different types of product ranges

- Reducing inventory replenishment errors

- Analysing sales and reaching optimal pricing

- Managing goods in transit

- Management of Advertisements & Promotions and Supplier Contributions

- Procurement Planning

- Tracking Free of Cost (FOC) Products

- Tracking advertisement and promotion expenses

- Controlling diverse inventories across multiple locations

- Order Processing

- Managing chargebacks, returned merchandise and multiple currencies

- Managing Bank Guarantee and LC Life Cycle with request and approval

- Forward Contract Management

- Receivable collection

- Asset Management

- Minimizing costs

Distribution ERP Software:

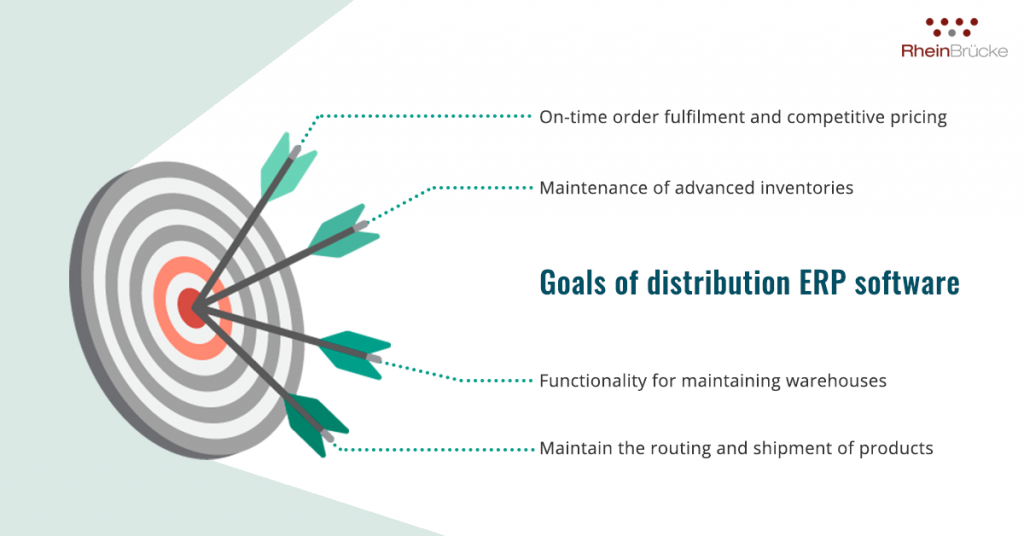

A distribution ERP software/tool is a management system integrated with business intelligence and customer relationship management (CRM) functionalities that offers end-to-end solutions for seamless management of distribution processes like logistics, order management, supply chain, finance, inventory management, fleet management, warehouse management, marketing, and shipping. It also provides significant insights into the purchase behavior of their customers.

What is the need of a distribution ERP software?

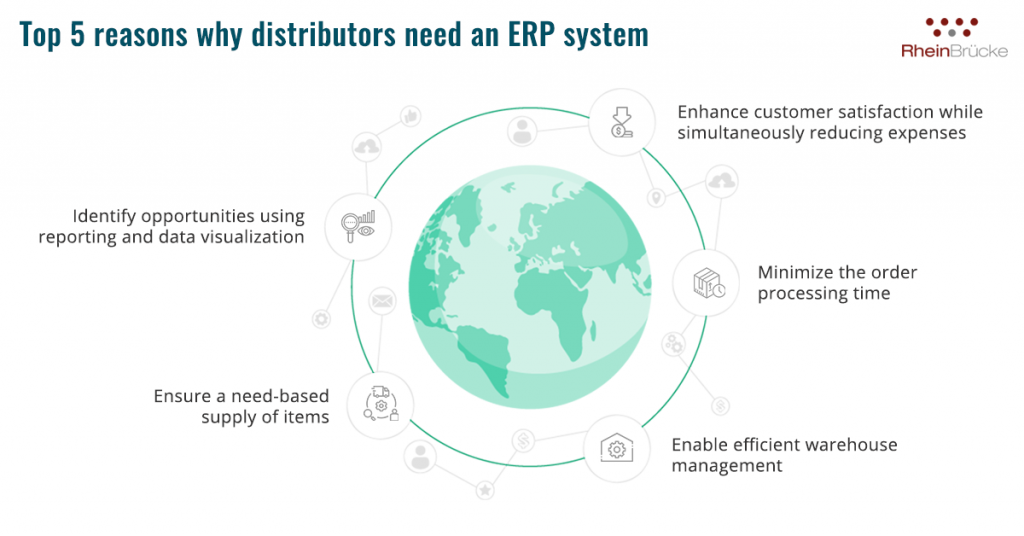

Distribution firms have multiple divisions, and errors in their workflows can lead to irrecoverable losses. ERP for distribution companies collects real-time data and gives comprehensive visibility into trends and operations in the organization. This helps companies to identify and address business issues more rapidly.

What are the essential features required in a distribution ERP software?

For a distributor, it is important to have a comprehensive insight into every aspect of the business. In addition, distributors must keep in mind the expenses associated with ordering, selling, transporting, and storing stock. To achieve success, it is necessary to keep these elements at a minimal or optimal level. A robust and comprehensive distribution ERP system can help to get a clear perspective of stock, streamline procedures, control operational expenditures, and meticulously necessitate surveillance for complete inventory management.

An ERP for distributors should be able to track every inventory transaction, minimize total inventory management expenses, increase stock turnover rates, reduce stock storage, centralize purchasing procedures, and much more. A system without the following basic components will be less successful in tackling the particular challenges distributors confront in their daily operations.

Effective supplier management:

Supplier management will allow distribution companies to communicate with all relevant stakeholders in real-time, including external partners and third-party shipping providers. Supplier management feature will be most essential for large distributors who handle high-volume orders and/or have several sites.

Order management:

It’s no secret that poor order management is a major source of concern for distributors. All orders, including those placed via eCommerce sites, are collected and stored in a single catalog for a quick inspection. Using the finest order management technology will not only allow distributors to process and monitor orders but also make it easier for them to prepare a bid or proposal and follow its progress.

A robust inventory management system:

ERPs for distribution businesses should have integrated warehouse management systems to oversee all operations pertaining to existing inventories. It should provide a complete picture of every asset activity, giving managers access to accurate inventory figures and data.

Logistics Management

Distribution ERPs should have features for transportation and logistics management. The logistics management solutions help them to streamline operations as well as cut costs by optimizing freight and container planning, route planning, etc.

Integrated HCM, CRM and account management tools:

An ERP suite when integrated with human resource, finance and accounts management, and customer relationship management offers full insight into back-office processes, increases staff engagement, and improves customer service management capabilities.

Business Intelligence and Analytics:

Distribution companies will benefit from advanced analysis and reporting, which transforms disorganized data into usable statistics. By increasing visibility across shipments, orders, and stocks, an ERP software with integrated analytics capabilities can give actionable insights to make better decisions for enhancing efficiencies and controlling costs.

Integration functionality:

Potential distribution systems should be evaluated based on their ability to readily connect with any existing platforms being used by the enterprise. Furthermore, API support is also provided by some vendors which could be used by the distributors to perform customized integrations with third-party apps.

How Modern Distributors are leveraging ERP Solutions to Enhance Efficiencies – Success Stories

RheinBrucke’s ERP solution for Distributors built on Epicor ERP offers full range of features to meet the needs of the distribution industry – Order management, Supply Chain Management, Warehousing, Supplier Relationship Management, Financial Management, Customer Relationship Management and more, to support your company’s growth with rapid implementation and easy expansion, no matter the size or diversity of your supply chain.

Recently, one of UAE’s prominent distribution and manufacturing company for auto-parts, partnered with RheinBrücke to overcome their business challenges. Since 2013, the organization was utilizing Epicor 9 to take control of their business operations and empower workers to accomplish goals. However, due to the significant rise in battery sales due to expansion in the automobile sector, they needed to upgrade their ERP to manage their growing warehouse management needs and enable them to effectively track the warranty of their shipments. and distribution management systems, allowing for faster turnaround times.

To achieve the objectives required by the company, our strategy was to integrate Epicor 10 and equip our client’s business with flexible and adaptable ERP software and that will help them to expand their business, innovate, and eliminate waste in all parts of the manufacturing process. We used business process reengineering to deploy Epicor 10 which in turn enhanced the distribution to multiple sales divisions. Functionalities like cost tracking and serial tracking were implemented which were necessary for maintenance and updates. Our team also designed a mobile application for Android and iOS that allows their QC and warehouse teams as well the end-customers to track the warranty of the products.

We also integrated Epicor’s unified Warehouse Management System with their order processing and production activities. They are now able to track their inventories in real-time. With real-time data gathering, inventory accuracy increased up to 24% thereby accelerating the order-to-ship cycle. The company was able to achieve an increase in process optimization by 15% and transaction speed by 32%.

Another customer of ours, one of the largest consumer services groups in Kuwait, involved in sales and distribution of an array of products including Pharmaceuticals, Consumer Health Care, Medical Equipment, Perfumes and Cosmetics, FMCG (Consumer and Food), & Cafes and Restaurants, has been able to streamline their processes and gain accurate, real-time insights based on a single version of the truth. It helped them save time, eliminate errors, and ultimately improve customer satisfaction.

Our solution for them was the implementation of Epicor ERP with enhancements designed to address some of their specific challenges in areas like Advertisement & Promotions, Tender Management, Procurement Planning, Purchase Order Processing, Shipment Tracker, Service Management, Order Processing, Warehouse Management, Inventory management, etc. It also included several features for managing user Security, Supplier Contribution, Cash/Bank Enhancement, Forward Contract Management, Supplier Payment Process, Recovery of expenses, Receivable Collection, and PDC Auto Allocation. Currency Trend Analysis, Asset Management with Requests and approval , and more.

Our solution combines powerful features of Epicor ERP along with numerous enhancements configured by RheinBrücke’s experts based on proven best practices aggregated from our multiple distribution industry implementations. Thus, the solution can be adapted quickly to meet the very specific needs of your business. This need is not addressed by many ERP vendors in the market now and can ensure more value from your ERP implementation.

Do you need assistance in selecting and implementing an ERP for distribution industry? Contact us.