ERP fatigue is real. For years, the same features have rotated through headlines; AI, blockchain, AR, rinse and repeat. But if you are in manufacturing, automotive, or construction, you are not buying buzzwords; you are buying control, clarity, and tangible outcomes.

Let’s cut past the hype. Here is what really matters in a modern ERP system in mid-2025, especially if you are running complex production lines, coordinating multi-tier supply chains, or managing project-heavy ops.

Component-Level Traceability with Reverse Drill-Down

Component-Level Traceability with Reverse Drill-Down

Gone are the days when serial number tracking was enough. Today’s ERP must track every component’s lifecycle, both forward and backward. If a quality issue emerges, you should be able to trace it not just to the assembly line, but back to the supplier’s supplier. Modern ERPs embed this into BoM, inventory, and service modules without making users dig through reports. The best systems offer visual traceability maps and real-time alerts, not just historical logs.

Why it matters: For automotive recalls or construction material audits, this level of granularity isn’t optional, it is survival.

Engineering Change Management (ECM) Built for Speed

Engineering Change Management (ECM) Built for Speed

Too many systems bolt on ECM as an afterthought. In manufacturing, engineering change requests, approvals, and implementations need to be native, not forced. And it must sync across design, production, and procurement instantly.

Think: When a supplier can’t deliver a spec part, can your ERP instantly reroute the entire BoM through change control before downtime hits?

Example: A Tier 1 automotive supplier was able to reduce change cycle time from 2 weeks to 2 days using a fully embedded ECM.

Dynamic Material Reallocation

Dynamic Material Reallocation

An intelligent ERP should optimize material distribution by:

1.Reprioritizing orders based on real-time demand shifts (e.g., expediting a delayed OEM order)

2.Substituting materials when supply chain disruptions occur (e.g., swapping 304 for 316 stainless steel if specifications allow).

3.Preemptively compensating for scrap rate variances.

Construction Application: If a shipment is delayed, the system should identify alternative suppliers before project timelines are affected.

Supplier Collaboration Portals That Actually Work

Supplier Collaboration Portals That Actually Work

Emailing POs and hoping for the best? That is over. The modern ERP integrates real-time supplier portals, not just for POs and ASNs but for quality checks, compliance docs, order commits, and early issue alerts.

Sustainable Manufacturing with Built-In Carbon Accounting

Sustainable Manufacturing with Built-In Carbon Accounting

Built-in carbon accounting systems enable manufacturers to accurately monitor and report emissions on a per-unit basis throughout the production process. These advanced tools not only provide real-time insights into a product’s environmental footprint but also recommend alternative, more sustainable materials that can help reduce overall emissions

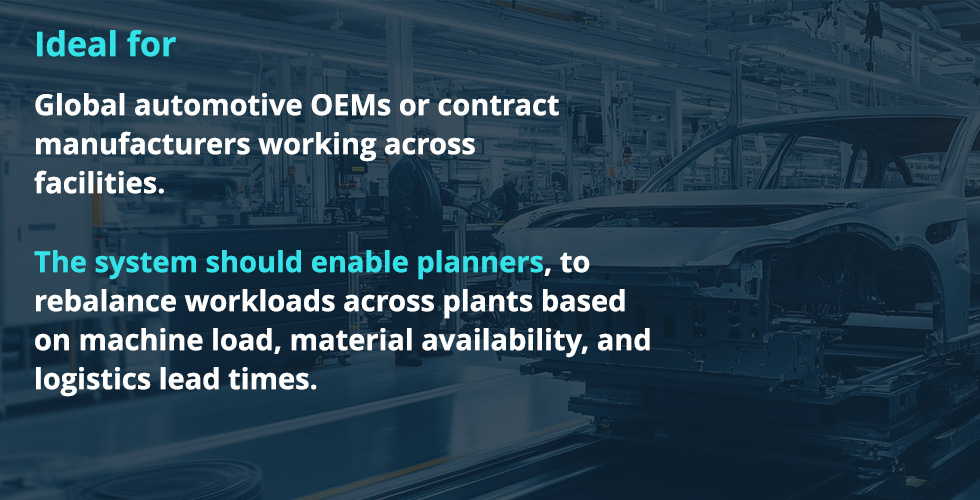

Cross-Plant Production Visibility

Cross-Plant Production Visibility

Most ERP systems are still plant-centric. But a tiered manufacturing model, say, sub-assemblies at Plant A, final assembly at Plant B, demands cross-plant order orchestration and shared capacity planning.

Integrated Maintenance, Production Scheduling & Predictive Analytics

Integrated Maintenance, Production Scheduling & Predictive Analytics

Preventive maintenance is common. But integrating predictive analytics into maintenance and production planning is a game-changer. Modern ERPs now forecast equipment failures based on sensor data and historical trends, rescheduling runs before issues occur. This ensures you never overpromise capacity or miss deadlines due to unplanned outages.

Use case: A machine scheduled for inspection or flagged for possible failure shouldn’t be assigned to a high-priority auto part run.

Best-in-class systems integrate IoT layers and machine data to trigger predictive maintenance before line-critical runs are scheduled.

Built-In Project Ops for Capex-Heavy Industries

Built-In Project Ops for Capex-Heavy Industries

Construction and infra businesses often live in spreadsheets for project costing and resource planning. A modern ERP brings WBS-based project tracking, budgeting, procurement, and time tracking under one roof, reducing the need for bolt-on project tools.

Bonus: Integration with asset lifecycle management for companies building, operating, and maintaining structures or machinery.

Intelligent Contract Manufacturing Management

Intelligent Contract Manufacturing Management

For firms using external manufacturers, modern ERPs provide real-time visibility into partner capacity, quality metrics, and delivery performance. The system can automatically redistribute orders when contractors fall behind schedule.

Modern ERPs analyze vendor throughput and auto-suggest load balancing or reallocation based on order urgency, compliance status, and historical reliability.

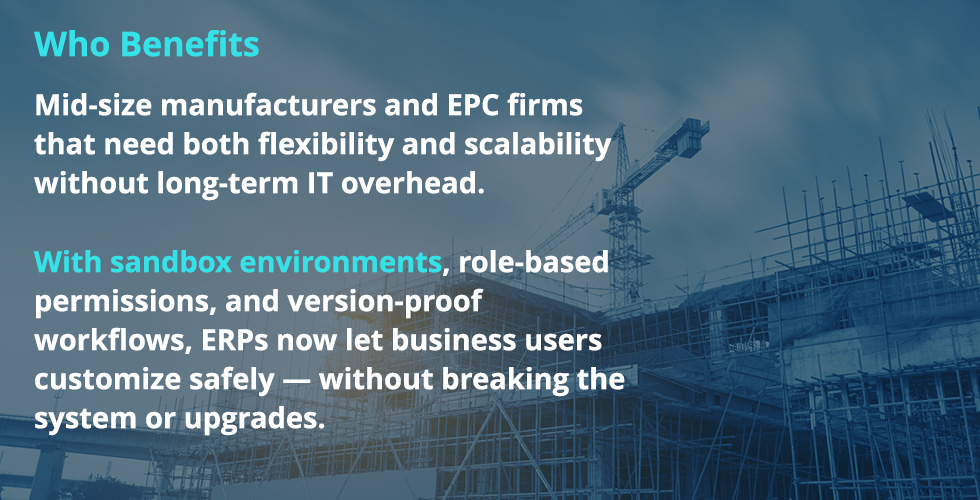

Low-Code, Cloud-Native Customization with Guardrails

Low-Code, Cloud-Native Customization with Guardrails

Customization is a double-edged sword. Modern cloud-native ERPs now offer low-code platforms with version-proofing, letting business users tweak forms, workflows, and dashboards without jeopardizing future upgrades. Modular deployment models allow you to phase in new capabilities without system-wide disruption.

Final Thought

ERP is not about how many acronyms it can pack into a slide deck. It is about how quietly and powerfully it handles the chaos of your day across machines, materials, teams, and timelines.

In manufacturing, automotive, and construction, the winners in 2025 will be the ones who stop chasing buzzwords and start asking better questions. What does not break under pressure? What scales without complexity? What just works?

If your ERP isn’t delivering quietly, powerfully, and predictably — it may be time to rethink your short list.