Few companies truly embody the spirit of the automotive aftermarket like Al Muqquram Auto Parts. Every interaction with them reminds me why relationships built on integrity and shared purpose stand the test of time.

A-MAP Group, a leading company in the global automotive parts distribution industry, embarked on a digital transformation journey to streamline operations and boost efficiency. With RheinBrücke’s expertise and Epicor Kinetic ERP, A-MAP achieved remarkable results, setting a new benchmark in operational excellence.

About A-MAP Group

Headquartered in Dubai, A-MAP is a subsidiary of the Badami Holding Group. The company specializes in distributing aftermarket automotive spare parts, batteries, and lubricants. With a global presence in China, South Africa, Nigeria, and Qatar, A-MAP represents top brands like Solite, Sebang, Rocket, and ADNOC Voyager lubricants.

Their 24×7 roadside assistance service ensures rapid response and customer satisfaction across regions.

The Challenges

As A-MAP expanded its global footprint, the company recognized opportunities to enhance operational efficiency and future-proof its business:

Modernizing Operational Processes: Existing manual methods for warehousing and inventory tracking provided a solid foundation but needed automation to improve speed and accuracy as the business grew.

Modernizing Operational Processes: Existing manual methods for warehousing and inventory tracking provided a solid foundation but needed automation to improve speed and accuracy as the business grew.

Siloed Operations: Several business-critical systems operated independently. Integrating these would enable a more connected view of operations and unlock greater agility.

Siloed Operations: Several business-critical systems operated independently. Integrating these would enable a more connected view of operations and unlock greater agility.

Need for Streamlining Workflows: Processes developed organically over time introduced complexity and redundancy, offering opportunities to simplify and optimize for higher productivity.

Need for Streamlining Workflows: Processes developed organically over time introduced complexity and redundancy, offering opportunities to simplify and optimize for higher productivity.

Need for Unified Insights: Data existed across the organization, but delivering real-time, unified insights would empower leadership to make faster, smarter decisions.

Need for Unified Insights: Data existed across the organization, but delivering real-time, unified insights would empower leadership to make faster, smarter decisions.

RheinBrücke’s Solution

To address these challenges, RheinBrücke implemented Epicor ERP and Warehouse Management System (WMS). Key improvements included:

To overcome these challenges, we deployed Epicor Kinetic ERP alongside a fully integrated Warehouse Management System (WMS). This combination automated inventory tracking, optimized order fulfillment, and Warranty Management, sales, and warehouse operations within a single digital ecosystem.

Key improvements included:

Streamlined Sales & Order Management

Streamlined Sales & Order Management

Automated order processing reduced errors and accelerated fulfilment.

By automating the entire order-to-fulfilment cycle within Epicor Kinetic ERP, sales teams now experience faster order entry, automatic validation, and instant allocation of inventory. This reduced manual errors, shortened processing time, and improved overall fulfilment accuracy — ensuring every order is picked, packed, and dispatched efficiently.

Optimized Inventory & Material Management

Optimized Inventory & Material Management

Real-time dashboards and FIFO processes improved stock visibility and turnover.

The integration of Epicor Inventory Management with real-time dashboards has given A-MAP complete visibility over stock levels across all branches. Intelligent FIFO (First-In-First-Out) logic ensures proper material rotation, minimizing ageing inventory and write-offs.

Enhanced Warehousing & Picking Operations

Enhanced Warehousing & Picking Operations

A-MAP’s warehouse operations were transformed through Kinetic mobile warehousing and a custom-built picking algorithm designed to handle both inward (receipts) and outward (order fulfilment) movements. The algorithm dynamically suggests the most efficient picking sequence based on product location, order priority, and load capacity — significantly reducing travel time and manual effort. The result: faster throughput, greater accuracy, and a paperless workflow from dock to dispatch.

Elevated Customer Experience

Elevated Customer Experience

Customer interactions have become more transparent and responsive with the adoption of digital proof of delivery and mobile RMA (Return Material Authorization) applications. These tools enable customers to track deliveries, initiate returns seamlessly, and receive prompt updates — strengthening trust and brand loyalty..

Data-Driven Insights

Data-Driven Insights

Epicor’s MIS empowered leadership with real-time analytics for faster decisions.

Epicor’s integrated Management Information System (MIS) delivers real-time performance metrics across sales, inventory, and warehouse functions. Dashboards and analytics now empower leadership teams to make faster, data-backed decisions — from identifying slow-moving items to optimizing branch-wise demand patterns.

Sustainable Operations

Sustainable Operations

Paperless processes supported A-MAP’s green initiatives.

By digitizing workflows and eliminating paper-based processes in sales, warehousing, and delivery documentation, A-MAP took a major step toward sustainability. The paperless operations not only reduced environmental impact but also improved data accuracy and traceability across departments.

Warranty Management

Warranty Management

Warranty claims are seamlessly managed through RheinBrücke’s Mobile Warranty Solution, fully integrated with Epicor Kinetic. The solution enables complete traceability from claim initiation to closure, linking directly with inventory and serial tracking to instantly validate product eligibility. Onsite inspections are conducted through the mobile app, which automatically creates RMAs for valid claims and notifies the Sales team to generate the corresponding replacement order. This end-to-end automation has eliminated manual verification, reduced processing time, and significantly enhanced customer responsiveness

Logistics Optimization

Logistics Optimization

The implementation optimized logistics planning through route visibility, consolidated dispatch scheduling, and performance tracking of delivery operations. Real-time updates from the WMS and ERP ensured efficient coordination between sales, warehouse, and logistics teams — minimizing idle time and maximizing delivery efficiency.

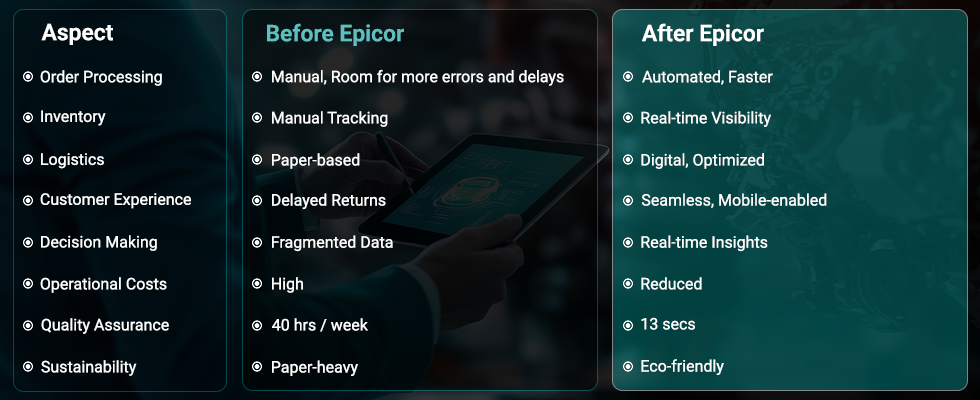

Before vs After: A Snapshot

Business Impact

1)Operational Efficiency: Automation reduced manual work and improved agility.

2)Cost Savings: Lower admin overhead and better resource allocation.

3)Inventory Accuracy: Minimized stockouts and overstocking.

4)Faster Decisions: Real-time data enabled quicker responses to market needs.

5)Customer Satisfaction: Faster deliveries and smoother returns boosted loyalty.

6)Sustainability: Paperless processes reduced waste and environmental footprint.

Conclusion

A-MAP’s ERP transformation with RheinBrücke and Epicor has redefined how automotive distributors can operate in a digital-first world. With streamlined operations, real-time insights, and enhanced customer service, A-MAP is now better equipped for sustained growth and success.